The New Capital power plant project is being executed by EEHC as part of the Egypt Megaproject, which involves the development of three 4.8GW natural gas-fired CCPPs and up to 12 wind farms with a combined capacity of 16.4GW by Siemens and the Government of Egypt.

Siemens was awarded multiple contracts worth €8bn ($8.94bn) for the development of the Egyptian power generation facilities in June 2015.

The contracts extend the memorandums of understanding (MOUs) signed during the 2015 Egypt Economic Development Conference (EEDC) held in Sharm El Sheik.

Siemens preferred Orascom Construction as its engineering, procurement and construction (EPC) partner to supply the power plant on turnkey basis.

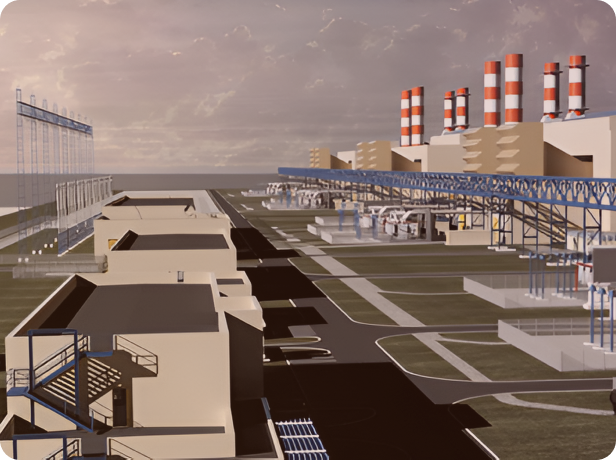

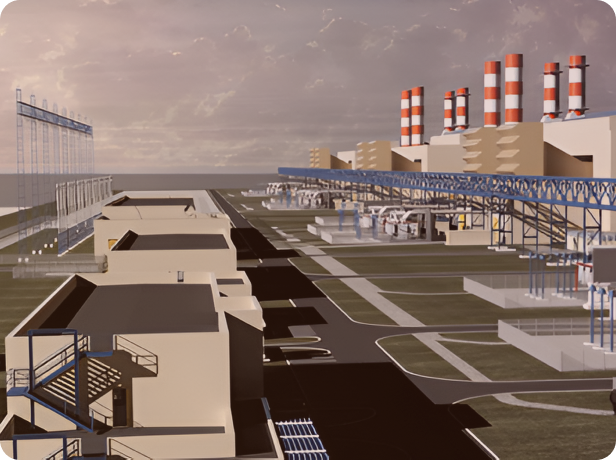

The project site of the power plant will extend over an area of 744,811m².

The plant will integrate eight Siemens SGT5-8000H high-efficiency combustion turbine generators (CTGs), eight Benson heat recovery steam generators (HRSGs), four SST-5000 steam turbine generators (STGs) and four air-cooled condensers.

Each combined-cycle module will have a rated capacity of 1,200MWe.The balance of plant (BOP) systems will include a diesel generator, transformers and switchgear as well as associated mechanical / electrical subsystems.

The dual-fuel plant will use natural gas as primary fuel and light fuel oil as a back-up fuel.

It will receive natural gas from a new underground connection pipeline, while light fuel oil will be supplied by trucks from Musturod or Helwan oil refineries.

A water treatment facility will be built on the site to supply potable water for the power plant.

The project will also integrate a wastewater treatment facility to treat liquid waste generated by the power plant.

Other ancillary infrastructure includes a logistics building, gas handling facilities, fuel feeding system, fire-fighting facilities, ventilation and air-conditioning systems, a chemical laboratory, and communication systems.

Elkrom Middle East is charged with the mechanical and electro-instrumental erection of two complete combined cycle units, each made up of 2 gas turbines, 2 Heat Recovery Steam Generators, one Gas Turbine and Air Cooled Condenser, as well as all relevant auxiliaries and BoP Piping.